As Section of Confidence® Extractables and Leachables Companies, our workforce offers comprehensive leachable analyses — including leachables screening analyses or Specific leachables concentrate on analyses — if much more thorough investigations are required.

This guideline complements the EMA’s method, furnishing more insights on environment HBELs for risk identification in shared services. It’s a crucial useful resource for handling cross-contamination hazards in multi-item environments.

The cleaning validation exercise shall be planned further for three consecutive batches While using the consideration of the validated cleaning treatment as placed on former batches.

If the very first swab sample result is from limit re-thoroughly clean the exact same products with an acceptable solvent or by water and exactly the same shall be dealt with for the duration of cleaning validation and.

one.four The objective of cleaning validation is usually to show that the equipment is continuously cleaned of product, detergent and microbial residues to an appropriate degree, to avoid probable contamination and cross-contamination.

A well known academic web site for pharmacy learners, pharmacy specialists and pharmaceutical gurus.

By staying informed and adopting best practices, pharmaceutical producers can sustain substantial benchmarks of cleanliness, secure affected person security, and make certain the caliber of their solutions within an at any time-evolving industry.

These guidelines make sure regularity and safety through the industry. Adhering to these polices is not pretty much compliance; it’s about guaranteeing the best high-quality of pharmaceutical products and solutions.

Immersion cleaning: This approach involves immersing parts of a chunk of equipment into a cleaning Alternative, tailored on the opportunity residues that need to be taken out.

Cleaning validation is the process of properly documenting the cleaning protocol. Therefore, cleaning validation is used to ascertain proof that the cleaning process will protect against product contamination. This validation is often a documented evidence that the cleaning system is efficient.

Through the use of NOEL and MACO, we can discover out the quantity of a drug that can not be performed above to the following batch. As experiments above 250mg /kg LD50 should not be website above 0.25gm in another batch as per over the batch has 350mg day by day dose and one hundred kg batch sizing.

• the description of the devices to be used, including an index of the products, make, product, serial range or other special code;

Productive sampling assists ensure that corporations can validate their products cleaning process or perhaps the cleaning techniques employed by their industrial cleaning workforce. What's more, it gives corporations with the data & aspects they need to have for thorough documentation.

Our Protection Analysis usually takes assessed extractables or leachables outcomes coming from an Extractables Evaluation or check here study or perhaps a leachables testing and correlates the info towards the individual problem.

Alisan Porter Then & Now!

Alisan Porter Then & Now! Kenan Thompson Then & Now!

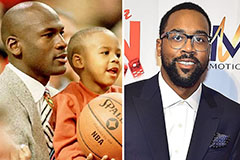

Kenan Thompson Then & Now! Marcus Jordan Then & Now!

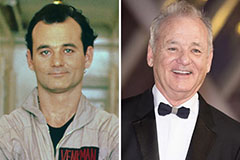

Marcus Jordan Then & Now! Bill Murray Then & Now!

Bill Murray Then & Now! Teri Hatcher Then & Now!

Teri Hatcher Then & Now!